Question 11

Which of the following are the MOST logical reasons for providing source inspection?

. The supplier has consistently shown poor out-going quality.

. The key inspection points are hidden after assembly at the suppliers' plant.

. The supplier requests the inspection to save them potential shipping expenses.

. The criticality of the product warrants it.

. The supplier has consistently shown poor out-going quality.

. The key inspection points are hidden after assembly at the suppliers' plant.

. The supplier requests the inspection to save them potential shipping expenses.

. The criticality of the product warrants it.

Question 12

What is the standard deviation of the values below?

4.5, 5.1, 6.2, 2.1, 3.9

4.5, 5.1, 6.2, 2.1, 3.9

Question 13

Compute the upper control limit for an s chart, based on a sample size of 10, if the process is in control with a mean of 40 and a sample standard deviation of 7.

Question 14

A comprehensive corrective action program is initiated at a large company. Input for CARs are received from customers, internal and external audits, material review reports and other sources. Which two of the following groups would usually administer and control the CAR process?

. Management review team.

. Quality department.

. Corrective Action Board.

. Material Review Board.

. Management review team.

. Quality department.

. Corrective Action Board.

. Material Review Board.

Question 15

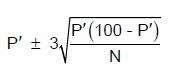

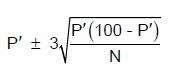

An electronics firm was experiencing high rejections in their multiple connector manufacturing departments. "p" charts were introduced as part of a program to reduce defectives. Control limits were based on prior history, using the formula:

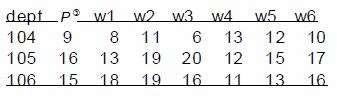

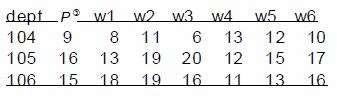

P' is the historical value of percent defective and n is the number of pieces inspected each week. After six weeks, the following record was accumulated

1,000 pieces were inspected each week in each department. Which department(s) exhibited a point or points out of control during this period (round off calculations to nearest tenth of a percentage point)?

P' is the historical value of percent defective and n is the number of pieces inspected each week. After six weeks, the following record was accumulated

1,000 pieces were inspected each week in each department. Which department(s) exhibited a point or points out of control during this period (round off calculations to nearest tenth of a percentage point)?