Question 11

A bicycle manufacturing company is implementing Dynamics 365 Supply Chain Management.

The warehouse must pick and stage parts other than paint for bicycle assembly. Paint is at the production station.

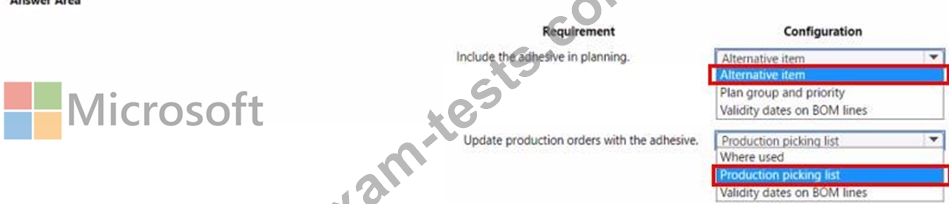

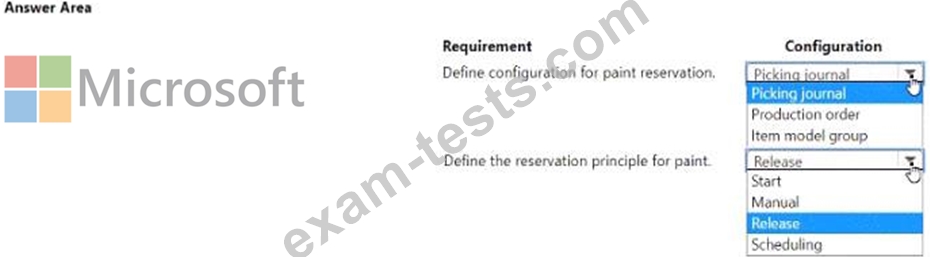

You need to configure the reservations for production.

What should you configure? To answer, select the appropriate options in the answer area.

NOTE: Each correct selection is worth one point.

The warehouse must pick and stage parts other than paint for bicycle assembly. Paint is at the production station.

You need to configure the reservations for production.

What should you configure? To answer, select the appropriate options in the answer area.

NOTE: Each correct selection is worth one point.

Question 12

A manufacturing company is implementing Dynamics 365 Supply Cham Management.

Bill of materials (BOMs) must be calculated using standard cost principles.

Miscellaneous charges must be included in the unit cost price. The explosion mode must arways be enforced as single level.

You need to configure the system to meet the requirements.

Which configuration should you enable for each requirement? To answer, drag the appropriate configurations to the correct requirements. Each configuration may be used once, more than once, or not at all. You may need to drag the split bar between panes or scroll to view content.

NOTE: Each correct selection is worth one point.

Bill of materials (BOMs) must be calculated using standard cost principles.

Miscellaneous charges must be included in the unit cost price. The explosion mode must arways be enforced as single level.

You need to configure the system to meet the requirements.

Which configuration should you enable for each requirement? To answer, drag the appropriate configurations to the correct requirements. Each configuration may be used once, more than once, or not at all. You may need to drag the split bar between panes or scroll to view content.

NOTE: Each correct selection is worth one point.

Question 13

You need to address the ignition switch issue.

Which three actions should you perform? Each answer presents part of the solution.

NOTE: Each correct selection is worth one point.

Which three actions should you perform? Each answer presents part of the solution.

NOTE: Each correct selection is worth one point.

Question 14

An electronics manufacturing company is transitioning from infinite capacity planning to finite capacity planning to improve scheduling efficiency and manage resource constraints effectively.

The company observes that its manufacturing process typically requires a minimum lead time of five days.

The company requires finite capacity scheduling to create realistic production schedules that account for resource limitations over a defined minimum lead time of five days.

You need to implement finite capacity planning with a time fence that aligns with the five-day manufacturing lead time.

Solution: Disable capacity reservations when scheduling production orders.

Does the solution meet the goal?

The company observes that its manufacturing process typically requires a minimum lead time of five days.

The company requires finite capacity scheduling to create realistic production schedules that account for resource limitations over a defined minimum lead time of five days.

You need to implement finite capacity planning with a time fence that aligns with the five-day manufacturing lead time.

Solution: Disable capacity reservations when scheduling production orders.

Does the solution meet the goal?

Question 15

A company that assembles packaging material uses Dynamics 36S Supply Cham Management.

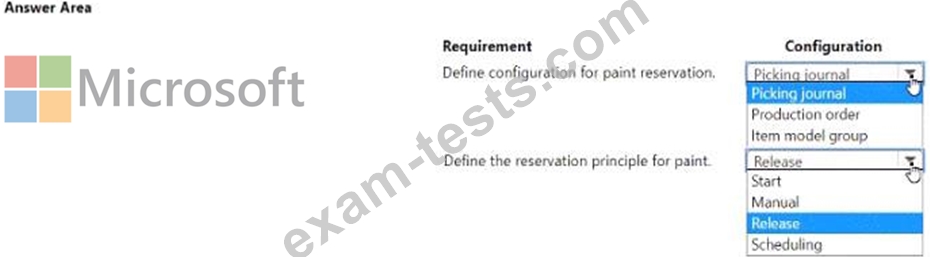

The glue that is used in assembly has run out of stock and will not be back in stock as expected. Another adhesive must be substituted for the glue. This will affect orders in planning as well as production orders that have started.

You need to ensure that the substitute adhesive is used in production until the glue is back in stock.

Which configuration should you use for each requirement? To answer, select the appropriate options in the answer area.

NOTE: Each correct selection Is worth one point.

The glue that is used in assembly has run out of stock and will not be back in stock as expected. Another adhesive must be substituted for the glue. This will affect orders in planning as well as production orders that have started.

You need to ensure that the substitute adhesive is used in production until the glue is back in stock.

Which configuration should you use for each requirement? To answer, select the appropriate options in the answer area.

NOTE: Each correct selection Is worth one point.